Swift Plant made contact after reading about our project for Walker Movements and we arranged a full survey at their premises in Leicestershire.

They had a workshop that had recently undergone a major refurbishment programme to include a new roof, offices and toilets all redecorated and the only thing missing was a new resin floor.

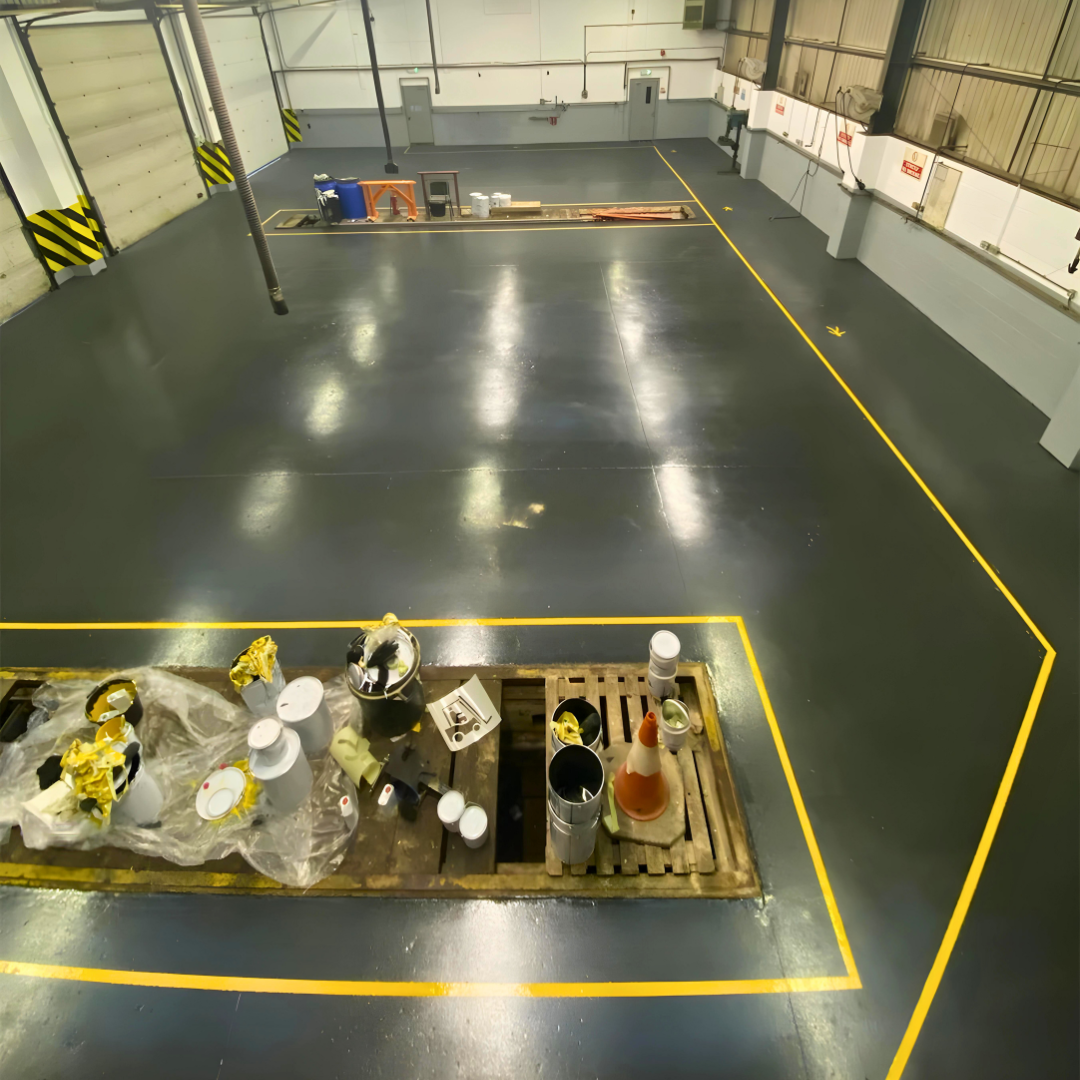

We agreed to the specification and submitted a quotation and a drawing of the ideas we proposed regarding layouts and colours.

The existing concrete floors were in a poor state of repair with flaking paint and a lot of oil staining.

All the concrete floors were mechanically prepared using our state-of-the-art, remote-controlled diamond grinders. These are virtually a dust-free system due to the latest in dust extraction whereby all the dust is collected at the source and directed into plastic bags which are fully sealed. Not only does this method protect our customers it also protects the operator.

Once the floor was fully prepared, we carried out localised repairs to the existing concrete. We then applied the first coat and let it cure overnight. Prior to applying the second coat, we inspect the finish and use a fine filler to further increase the final finish. We then sand the floor before applying the final coat of epoxy coating and allow it to cure. We then marked out and applied the safety demarcation around the inspection pits and the walkway. We also included a safety yellow walking man logo to show the nearest fire points. The floor was treated with a slip-resistant finish as the floor is a Workshop and will experience a lot of vehicle and foot traffic.

The project was completed over a 3-day period.

The floors are specified after consulting with the client to ensure we answer all their requirements, as per BS8204-6.